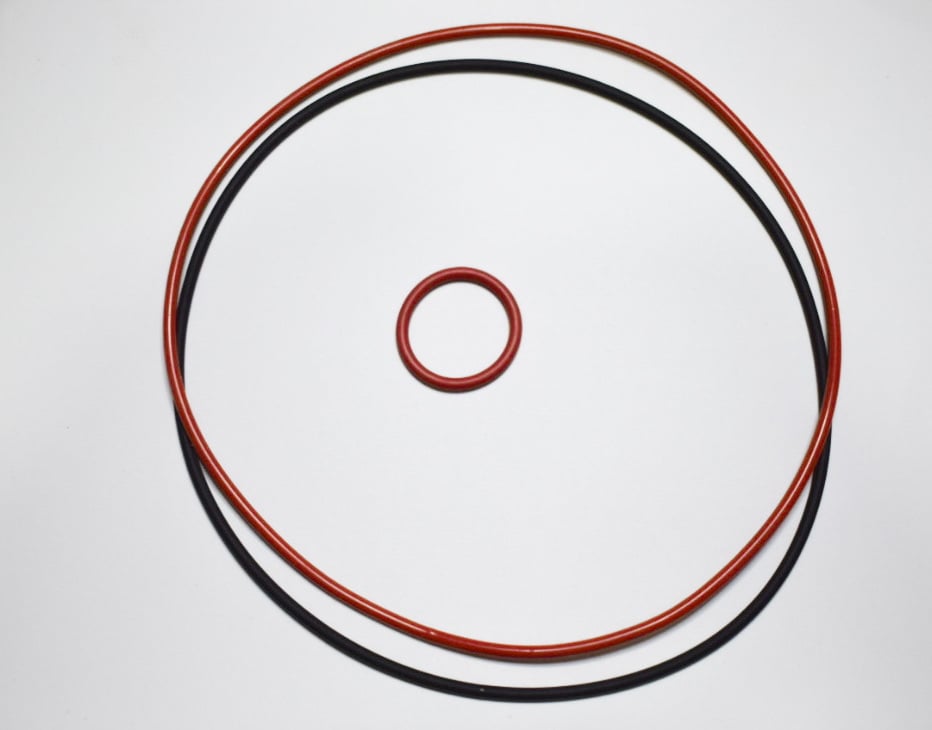

FEP/PFA Encapsulated O-Rings

ROW Incorporated

Extreme Seal

TFE-O-SIL® Silicone, Viton™ or EPDM O-Rings encapsulated with FEP or PFA are designed to address the growing problem of sealing in the most hostile chemical and temperature environments. TFE-O-SIL® combines the best qualities of two materials, FEP or PFA on the outside with its chemical inertness and an elastomer on the inside for resilience. This unique combination forms a highly effective, long lasting seal for the most demanding applications.

- Superior chemical resistance and durability in extreme temperatures.

- Their dual-material design combines resilience and chemical inertness for a long-lasting, effective seal.

Recommendations on application design and material selection are based upon available technical data and are offered as suggestions only. Each user should conduct evaluations to determine the suitability for his particular application. ROW, INC. offers no express or implied warranties concerning the form, fit, or function of a product in any application.

Square cross-section TFE-O-SIL® Rings can be used in applications where a larger sealing surface is needed to effect a more positive seal. These Rings require less squeeze than standard O-Rings for sealing and utilize the same groove dimensions.

Small ID Encapsulated O-Ring Ovality

Standard TFE-O-SIL® O-Rings in round or square cross-sections are manufactured in sizes to AS 568A industry standards. Non-standard sizes are also available for custom designs, along with a full range of metric (ISO) sizes.

Resilience and Chemical Resistance Redefined

TFE-O-SIL® O-Rings are available in over 60 standard cross-section sizes from .063" (1.60mm) to 1-1/4" (31.75mm). Standard TFE-O-SIL® O-Rings are comprised of FEP over Silicone, Viton™, or EPDM, and can be used in temperatures from -75° to +400°F (-60° to +205°C) depending upon the choice of elastomer core.

For high temperature applications to 500°F (260°C), TFE-O-SIL® is made with PFA over silicone. PFA has higher mechanical strength than FEP or TFE at elevated temperatures and has excellent crack and stress resistance.

Encapsulated O-Rings are primarily used as a static seal (axial or radial).

FEP-encapsulated O-Rings (Fluorinated Ethylene Propylene):

- Outstanding chemical and corrosion resistance

- Low coefficient of friction

- Resilience with choice of elastomeric cores

- Low compression set

- Temperature range: -75°F to 400°F (-60°C to 205°C)

- Unlimited sizes (No tooling charges)

- Solid & hollow silicone, Viton™ cores

- FDA compliant materials available

- USP Class VI approved materials available

PFA-encapsulated O-Rings (Perfluoroalkoxy). Same as FEP above but with these added benefits:

- High temperature applications to 500°F (260°C)

- Higher mechanical strength

- Better flex-life

- Low vapor permeation

- Excellent stress and crack resistance

- Longer wearability

- Solid silicone & Viton™ core

Square Cross-Section Ring Seals. Same as FEP above plus:

- Retrofits into standard O-Ring groove

- Larger sealing surface

- Less squeeze required for sealing

- Effects more positive seal

- Rectangular cross-sections also available

- Solid silicone & Viton™ core

*Orders are not refundable

![5[1] 5[1]](https://row-inc.com/hs-fs/hubfs/5%5B1%5D.png?width=200&height=200&name=5%5B1%5D.png)